Taste of Bread: From Consumer to Analytical Approach

The relationship between the expert and the consumer

The smell, taste, flavor and texture of bread are the consumer’s major quality criteria and are naturally the main concern of the bakery. As there is no measuring equipment that can precisely evaluate these criteria, tasting panels are used, whose members can judge the same sensory stimulants that will be perceived by the consumer: the smell of a brioche, the taste of rye, an acid flavor, a crispy crust. Such tasting sessions create a link between the world of consumer taste, the world of baking technology and of physicochemical analysis. The market is influenced by innovation and fashion so the product needs to be carefully placed in the right context and with the right references for the moment. Tasters undergo regular training based on tests of new products so that their reference notes are constantly updated.

Complex research tools

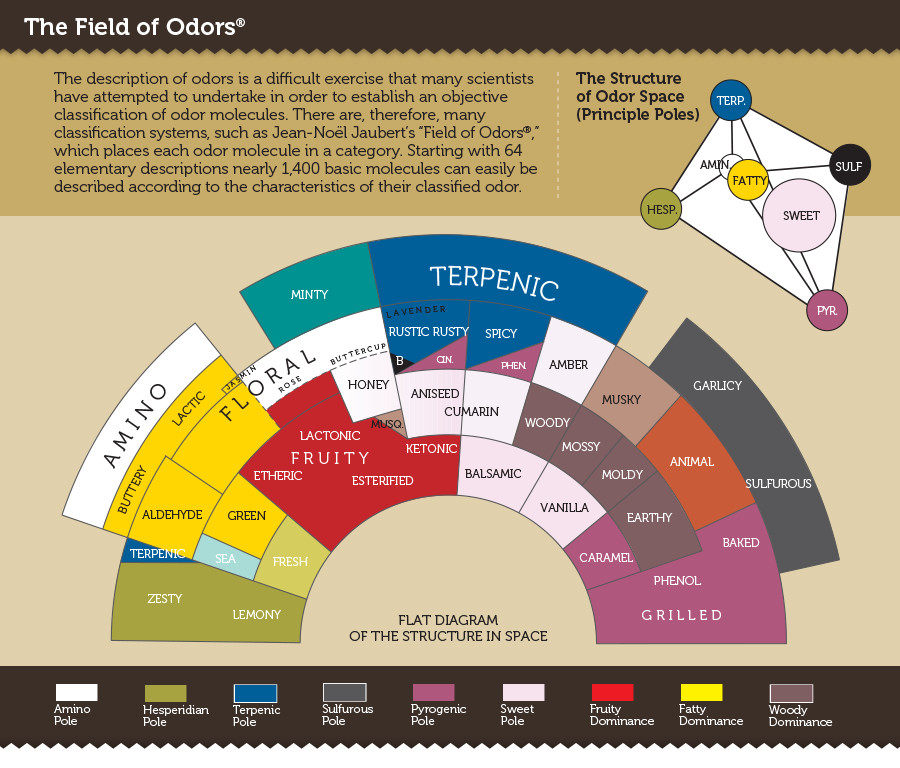

To analyze an odor extracted from bread it is necessary to separate and then identify the different components of the aroma. In a gas chromatograph, the molecules of the aroma are vaporized and then carried in a vector gas under pressure through a thin tube several meters long called a “column.” Some of the molecules partially attach themselves to the material, which slows them down. The size and the mass of the molecules will thus influence their speed of migration. Two types of detectors are used to identify them:

- The mass spectrometer, to give a name to the molecules detected;

- The human nose, to evaluate the odorous strength of these molecules

By combining gas chromatography and mass spectrometry (GC/MS) one can identify components according to their retention time and their mass. However, the molecules identified by GC/MS are not necessarily those that influence the smell of the bread and there can be important odor molecules which remain at the bottom.

The olfactometry, or sniffing tests, carried out at the end of the “column” (see box) complete the analysis, by submitting a mixture of volatile odorous components to the human nose. It requires the perception levels of the “nose panel” to pick up odors that are lost at the bottom level which the chromatograph cannot identify. The research is refined by determining the aromatic descriptions and the retention times corresponding to those particular molecules. Not all identified components contribute in the same way to the overall aroma of the product. By combining olfactometry and gas chromatography, mixed up molecules are separated and then individually smelled by a trained person. This identification compares and classifies the various molecules among themselves.

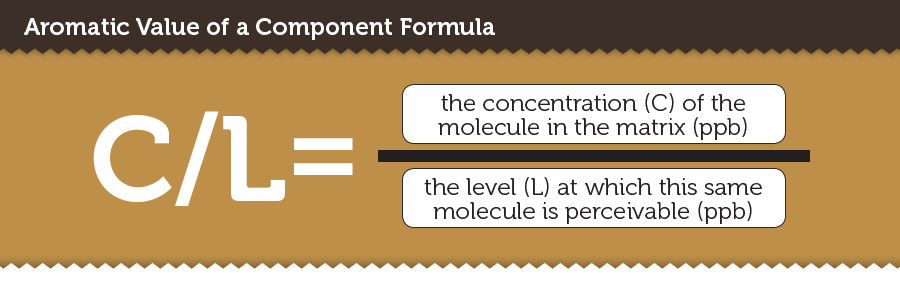

Depending on the perception level of the molecule, a person can either detect it or not and qualify it with a description. The quantitative importance of a component does not necessarily mean that it has a major role from an olfactory point of view. So the aromatic value of a component has to be considered according to the following formula:

The order in which the ingredients are added has some effect on the taste. The inclusion of salt right at the start of the kneading process has a positive effect, as the salt will be perfectly distributed in the dough and can effectively limit oxidation.

This enables the evaluation of what a particular component contributes to a mixture, an aromatic preparation, or an aroma, called an “odor power.” For example, 2.5 dimethyl pyrazine has a direct olfaction perception level of 800 ppb, while for acetic acid it is 22,000. In the same concentration, the 2.5 dimethyl pyrazine would have an aroma value 27 times higher! The higher this factor, the more the molecule is likely to contribute to the aroma of the product. The advantage of this technique is that in many cases the human nose is more sensitive than electrochemical sensors, such as ionization detectors or mass spectrometers.

A member of the “nose” panel in full concentration

Sensory analysis at Lesaffre

The preferences of bread consumers leading to a purchase include individual parameters such as mood and social context, the purchase environment at the point of sale, the presentation of the bread and, above all, the sensory characteristics of the bread. But can one explain and anticipate consumers’ reactions? This is the objective of sensory analysis, which contributes to the development of new products through testing by tasting panels.

The use of pertinent and discriminative descriptions allows the precise characterization of feelings. “There are several levels of tasting panels at Lesaffre,” explains Camille Dupuy, head of the sensory analysis laboratory. “Firstly, there is a panel of novices who carry out triangular differentiation tests. Then we have qualified and expert panels who have received undergone. They are able to evaluate sensory intensity on a notation scale and to refer to precise descriptions. They have also learned to distance themselves from their personal references and from intuitive reactions.”

The expert panel was set up in 2003 to describe the textures of crust and loaf of various bread products: white bread, brioches, baguettes, pita bread. The experience that Lesaffre has acquired on a worldwide level enables it to adapt more easily to clients’ requirements.